This is the cotton we use

- Better Cotton

We partner with Better Cotton to improve cotton farming globally. Better Cotton’s mission is to help cotton communities survive and thrive, while protecting and restoring the environment. Through its implementing partners, Better Cotton trains farmers to care for the environment and respect workers’ rights and wellbeing. Better Cotton is sourced via a system of mass balance and is not physically traceable to end products.

- Cotton made in Africa

Since 2009, we have been proud partners of the Cotton made in Africa (CmiA) initiative, an internationally recognized standard for sustainable cotton grown by African smallholder farmers. Through our collaboration, these smallholder farmers deepen their knowledge of sustainable agriculture and environmental protection. The CmiA-verified cotton we source for our products has minimal environmental impact and contributes to supporting village communities in Africa. For instance, the use of genetically modified seeds is prohibited, and the application of pesticides and herbicides is strictly regulated.

Furthermore, the initiative actively engages in social projects, including initiatives related to women’s empowerment, education, and health. It invests the revenue from licensing fees back into the cotton-growing regions. Cotton made in Africa is procured through a mass balance system and cannot be physically traced to end products.

- Organic Cotton and Cotton from the conversion

In comparison to conventional cotton, organic cotton has less impact on the environment and biodiversity as well as on the health of the farmers. In the cultivation of organic cotton, the use of artificial fertilizers, pesticides, and herbicides is prohibited. At the same time, crop rotation must be carried out so that different crops being grown on the agricultural land are alternated. This improves soil fertility and increases the humus content so that the soil can absorb more CO2. Furthermore, no chemical defoliants may be used which facilitate the mechanical harvesting of cotton but are also potentially hazardous to health.

In order to ensure that our products also contain organic cotton, we use established standards such as Textile Exchange for internal assurance in our supply chain. This ensures reliability of the raw material from the yarn all the way to the end product.

To further strengthen the use organic cotton, we also employ cotton from the conversion phase. What that means: Converting to organic cultivation can take up to three years. During this transition period, farmers follow the principles of organic farming until the cotton is officially certified as organic.

- Empowering Farmers

FIELD TO FASHION. With Empowering Farmers, we support Indian farmers in transitioning to organic cotton farming. By directly connecting with farm cooperatives, we lay the foundation for a traceable and certified supply chain. Switching to organic farming can take up to three years, making it a lengthy process for farmers. During the transitional phase, the harvest is typically smaller, and the cotton does not yet command a higher organic price. To bridge this gap, we provide an extra payment to the farmers. Our goal is to encourage them to make the switch and strengthen their livelihoods and those of their families. Additionally, we recognize their contribution to the environment. Organic farming avoids the use of chemical fertilizers and pesticides. Through our local partner, farmers also gain access to training, more affordable seeds and support for certification.

- Recycled Cotton

We use recycled cotton so we can rely on materials that have already been used in order to produce fewer new materials. For example, the recycled cotton may come from used clothing or household textiles. In doing so, we rely on established certification systems, such as Textile Exchange, to ensure that our products actually contain recycled cotton.

From Wool to Leather

Animal fibers and materials make up only a small part of our product portfolio. However, it is important to define specific requirements here because this area poses risks to animal welfare in particular. Our Animal Protection Guideline is the cornerstone of our actions. In our product portfolio, we have banned animal fibers and materials for which we cannot ensure that animal welfare standards have been upheld.

These include real fur, mohair, and angora.

- More Responsible Sheep’s Wool

Wool is one of our most important animal materials. Our animal welfare policy prohibits the use of wool from sheep that have been mulesed. This means that strips of skin have been removed to prevent fly infestation. This is often done without pain relief.

We also use wool that fulfils animal welfare criteria and recycled wool. This is backed up by internationally recognised standards, for example from Textile Exchange.

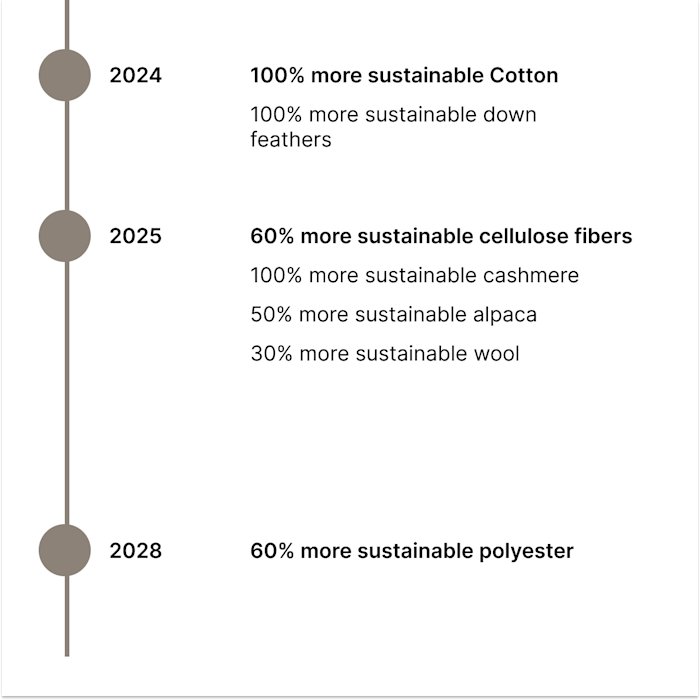

Our goal: 30% more sustainable wool in 2025. In 2024, 16% of the wool in the main material came from more sustainable sources.

- The Good Cashmere Standard®

We joined The Good Cashmere Standard (GCS) initiative in 2021. GCS focuses on animal welfare to improve the welfare of cashmere goats. The standard also focuses on social, economic and ecological criteria in order to positively change the lives of farmers and minimise negative environmental impacts. In the future, we want to completely eliminate the use of conventional cashmere.

Our goal: 100% more sustainable cashmere in 2025. In 2024, almost 64% of the cashmere in the main material came from more sustainable sources.

- More Responsible Down

Our Animal Welfare Policy prohibits the use of feathers and down from live plucking and from geese raised for force-fattening.

Since 2023, 100% of our feathers used come from sustainable sources. They are either recycled or come from certified supply chains to ensure responsible sourcing.

- Leather Working Group

In accordance with our Animal Welfare Policy, we only use leather sourced as a by-product of meat production. At the same time, we also prohibit the use of exotic leathers and leather from endangered species.

In 2021 LIEBESKIND BERLIN joined the Leather Working Group (LWG). This provides us with more transparency in our leather supply chain.

Since 2022, LIEBESKIND BERLIN only uses leather from LWG-certified tanneries. This conserves resources and reduces the environmental impact of the tanning process, which is known for its high use of chemicals, water, and energy.

- Alternatives

Today, we already offer a wide range of products made from non-animal materials. Our aim is to expand this offering even further in the future. In order to consider sustainable and environmentally friendly factors in addition to quality, our Product Development team is continually looking at innovative alternative materials.

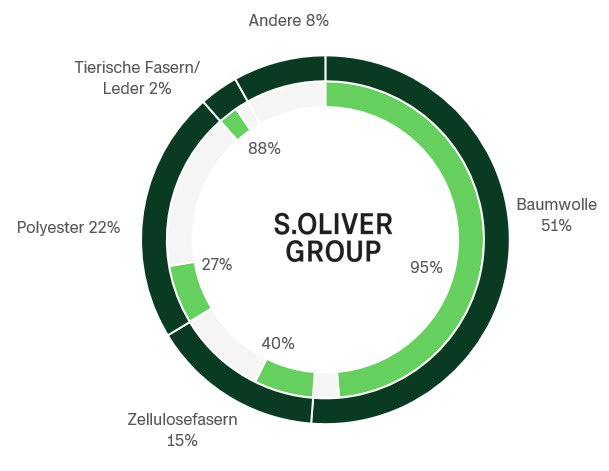

Cellulose Fibers

Cellulose fibers, such as viscose, modal, and Lyocell, are produced from renewable raw materials, including wood in particular. Unlike other synthetic fibers, such as polyester, they are distinguished by the fact that they are biodegradable thanks to their cellulose base.

However, there are risks involved in the supply chain: in sourcing cellulose, clearing trees, and preparing the material. The process is particularly resource-intensive due to the use of chemicals and the use of water and energy.

Our Goal: 60% sustainable cellulose fibers in 2025. 2023 almost 30% of cellulose fibers we used in production came from sustainable sources.

- More Responsible Cellulose Fibers from the Brand Lenzing

The viscose fiber LENZING™ECOVERO™ from the brand Lenzing originates from certified, controlled forestry and bears the EU Ecolabel thanks to its environmental sustainability. Thanks to its closed manufacturing cycle, the production of LENZING™ECOVERO™ causes about 50% less emissions and less water pollution than conventional viscose. And it’s a similar story for the production of modal and Lyocell fibers from the brand TENCEL™.

For the production of Lyocell, Lenzing not only uses certified wood, but also fabric remnants leftover from cutting cotton clothing from the textile industry. Raw materials are processed into new TENCEL™ Lyocell fibers using REFIBRA™ technology, significantly reducing the use of raw materials and energy.

TENCEL™, REFIBRA™, LENZING™, and ECOVERO™ are the brands of Lenzing AG.

- More Responsible Viscose from BIRLA CELLULOSE™

Similarly, our partner Birla Cellulose™ specializes in obtaining fibers from wood. Only wood from certified forestry is used for the production of the cellulose fibers from LIVAECO™. This makes it possible to trace fabrics back to their origin. Both water consumption and greenhouse gas emissions are significantly reduced in the manufacturing process compared to other non-certified natural fibers.